Comprehensive Guide to Grove Crane PDF Manuals

Grove Cranes are renowned for their reliability and efficiency in the construction and lifting industries. To ensure optimal performance, operators and technicians rely on comprehensive manuals that provide detailed instructions for operation, maintenance, and service. This article explores the invaluable resources available in Grove Crane PDF manuals, offering insights into their structure, content, and accessibility. Whether you’re a seasoned professional or a newcomer to the field, these guides are essential for mastering the intricacies of Grove Crane systems.

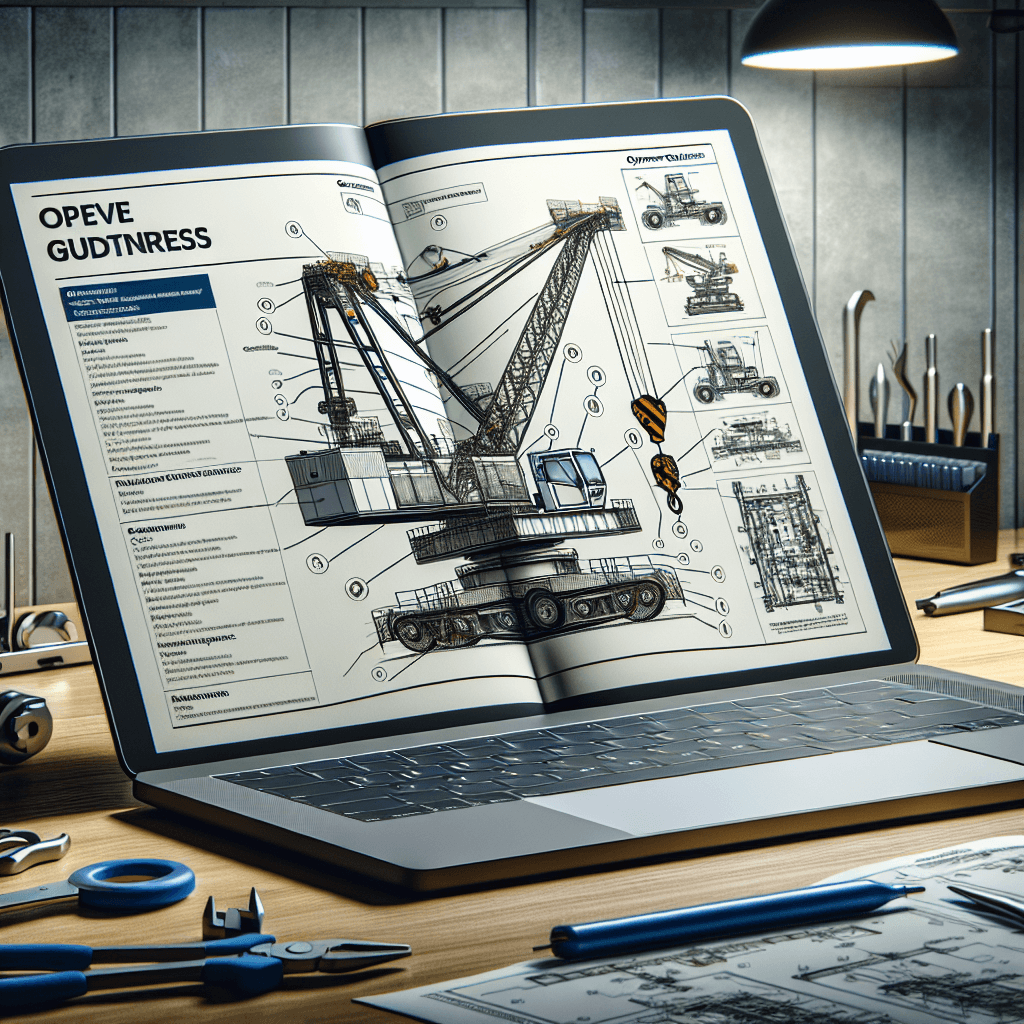

Grove Crane PDF manuals serve as the cornerstone for understanding the complex machinery involved in crane operations. These documents are meticulously crafted to cover every aspect of crane functionality, from basic operations to advanced troubleshooting techniques. Users can easily navigate through sections dedicated to specific crane models, ensuring that the information is relevant and precise for their particular equipment. The manuals are designed to be user-friendly, with clear illustrations and step-by-step instructions that facilitate a thorough understanding of the crane’s mechanics.

One of the standout features of Grove Crane PDF manuals is their accessibility. Available for download from Grove Crane Manuals, these documents can be accessed anytime and anywhere, providing users with the flexibility needed in dynamic work environments. The digital format ensures that the information is always up-to-date, reflecting the latest advancements and modifications in crane technology. This ensures that operators and technicians are always equipped with the most current data, enhancing the safety and efficiency of crane operations.

Moreover, these manuals are an invaluable resource for training and development. New operators can benefit from the comprehensive guides that introduce them to the basic principles of crane operations, while experienced technicians can delve into more complex topics such as hydraulic systems and electrical schematics. By providing a structured learning path, Grove Crane PDF manuals help bridge the knowledge gap and promote a culture of continuous improvement within organizations.

Detailed Schematics for Grove Crane Operations

The detailed schematics available in Grove Crane manuals are critical for understanding the intricate systems that power these machines. These schematics provide a visual representation of the crane’s components, showcasing how each part interacts with the others to perform complex lifting tasks. This visual aid is essential for both operation and maintenance, allowing users to quickly identify and address potential issues.

For operators, these schematics offer a clear understanding of the crane’s mechanics, enabling them to make informed decisions during operation. By familiarizing themselves with the layout and function of each component, operators can anticipate potential problems and take proactive measures to prevent them. This not only enhances safety but also optimizes the crane’s performance, leading to more efficient job completion.

Technicians, on the other hand, rely heavily on these schematics for troubleshooting and repairs. The detailed diagrams provide insight into the crane’s hydraulic and electrical systems, making it easier to pinpoint faults and implement solutions. By having a clear roadmap of the crane’s internal workings, technicians can perform maintenance and repairs with greater accuracy and speed, minimizing downtime and maximizing productivity.

Access to these detailed schematics is made easy through Grove Crane Manuals, where users can download the necessary documents specific to their crane model. This ensures that the information is tailored to the user’s needs, providing a customized approach to crane operation and maintenance. The availability of such precise and detailed schematics underscores the commitment to quality and efficiency that Grove Cranes are known for.

Essential Instructions for Grove Crane Maintenance

Maintenance is a critical aspect of ensuring the longevity and reliability of Grove Cranes. The PDF manuals provide essential instructions that guide users through the routine maintenance processes necessary to keep the cranes in optimal working condition. These guidelines are meticulously detailed, covering everything from daily checks to more extensive periodic inspections.

The manuals emphasize the importance of regular maintenance checks, outlining specific procedures to follow before, during, and after crane operations. Operators are provided with checklists that ensure all critical components are inspected, reducing the risk of unexpected failures. By adhering to these guidelines, operators can maintain the crane’s performance and prevent costly repairs.

In addition to routine checks, the manuals also cover more in-depth maintenance tasks. These include procedures for lubricating moving parts, inspecting hydraulic systems, and testing electrical components. Each task is described in detail, with step-by-step instructions and safety precautions clearly outlined. This comprehensive approach ensures that all aspects of crane maintenance are addressed, promoting a proactive maintenance culture.

For those seeking to enhance their maintenance skills, the manuals available at Grove Crane Manuals offer a wealth of information. Users can access detailed guides tailored to their specific crane model, ensuring that maintenance activities are conducted with precision and care. By following these instructions, operators and technicians can extend the lifespan of their equipment, ensuring that Grove Cranes remain a reliable asset on any job site.

Service Protocols for Efficient Grove Crane Use

Service protocols outlined in Grove Crane PDF manuals are designed to enhance the efficiency and reliability of crane operations. These protocols provide a structured approach to servicing, ensuring that all critical components are regularly checked and maintained to prevent unexpected breakdowns. By following these guidelines, operators can ensure that their cranes are always ready for action.

The service protocols begin with a comprehensive overview of the crane’s operational requirements, including load capacities, environmental considerations, and safety precautions. This foundational knowledge is crucial for operators to understand the limits and capabilities of their equipment, enabling them to plan and execute lifting tasks effectively.

In addition to operational guidelines, the manuals detail the steps necessary for routine servicing. This includes procedures for inspecting structural components, testing safety systems, and verifying the functionality of control mechanisms. By following these protocols, operators can identify potential issues before they escalate, ensuring that the crane remains in top working condition.

Access to these service protocols is facilitated through Grove Crane Manuals, where users can download the necessary documentation for their specific crane model. This ensures that all service activities are conducted in accordance with the manufacturer’s recommendations, promoting safety and efficiency on the job site. By adhering to these protocols, users can maximize the productivity and reliability of their Grove Cranes, ensuring successful project outcomes.

In conclusion, Grove Crane PDF manuals are an indispensable resource for anyone involved in the operation, maintenance, and service of these powerful machines. By providing comprehensive guides, detailed schematics, essential maintenance instructions, and structured service protocols, these manuals equip users with the knowledge and tools needed to ensure safe and efficient crane operations. Accessing these resources through Grove Crane Manuals ensures that operators and technicians have the most up-to-date and relevant information, fostering a culture of excellence and reliability in the field.